Purchasing Opportunity Crudes? Get Help in Anticipating and Solving Crude Fouling, Coking, and Water Emulsion Problems before they Happen.

Today, with the high cost of crude oils refineries cannot afford to pass up purchasing lower cost, opportunity crude oils. However, purchasing the wrong crude oil can cause stable water emulsions in the desalter, foul preheat exchangers, and/or coke up pipestill furnace tubes. If this happens, refineries can lose more than the advantage of purchasing the crude. Therefore, have your prospective crudes tested by Soluble Solutions to determine in advance if they will cause emulsion, fouling, and/or coking problems. Rely on the techniques, models, and understanding of Dr. Irv, the one who first discovered that crudes can be incompatible on blending. In addition, Dr. Irv has discovered that crudes can be self-incompatible and can even foul if they are barely compatible. Thus, it is even more important to have prospective crudes tested by Soluble Solutions to assure that your purchase decision results in an economic success and not a costly mistake. (See: World Refining, Oct. 2001, Pages 24-28 or click here to learn more about the Oil Compatibility Model)

Crude Oil Incompatibility on Blending

When crude oils are blended in the wrong proportions or even the wrong order, they can precipitate asphaltenes (called incompatibility). Once precipitated, it is difficult to redissolve asphaltenes quickly. Meanwhile, precipitated asphaltenes can cause stable oil-water emulsions, fouling of heat exchangers, and catastrophic coking of distillation furnace tubes. Although most crude oils are compatible on blending, the numbers of pairs of incompatible crudes are above 500. Any refinery that actively purchases opportunity crudes has probably already processed incompatible crudes. Dr. Irv not only was the first to offer scientific proof that incompatible crudes exist but he was the first to develop tests for individual crudes and a solution thermodynamic model that can predict which blends of any number of crudes are incompatible. These have been published in two papers in the first issue of Energy and Fuels of the new millennium (Jan. 2000, pp 56-59 and 60-63). More important, it is clear that Soluble Solutions is the place to contact before purchasing any new crudes in the future. Only Dr. Irv can anticipate and solve crude oil fouling problems before they happen.

Self-Incompatible Crudes

There exist a few (more than 30) crude oils that are actively traded that contain insoluble asphaltenes even without blending with other crudes. Thus, these high fouling crudes should either be declined for purchase or processed in special ways to redissolve the asphaltenes. Again, Dr. Irv was the first to discover self-incompatible crudes. However, his present tests are set-up to detect self-incompatible crudes as well as incompatibility from blending crudes. This topic was first presented by Dr. Irv at the United Engineering Foundation Conference on Heat Exchanger Fouling in Devos, Switzerland on July 12, 2001. Nevertheless, refineries are purchasing self-incompatible crudes every day. By sending Soluble Solutions a sample of a crude before purchase, you can avoid your refinery from being one of those.

Barely Compatible Crude Oils

Dr. Irv has discovered that either individual crudes or crude blends can be moderately fouling if they are barely compatible. This is because asphaltenes in such crudes still have a strong tendency to adsorb on metal surfaces to cause fouling and at water interfaces to form stable emulsions. Fortunately, Dr. Irv’s tests and model can be used to measure the distance from incompatibility and predict if this type of fouling and emulsion formation is to be expected. A paper on this topic was presented by Dr. Irv at the Second International Conference on Petroleum and Gas Phase Behavior and Fouling in Copenhagen, Denmark on August 27 – 31, 2000. Click here to download a copy of this paper

Need more Information on Crudes?

Contact PetroTech Intel to order custom crude assays, to use PTI’s Crude Information Management System (CIMS), or to get PTI Intelligence Reports.

Oil Compatibility Model

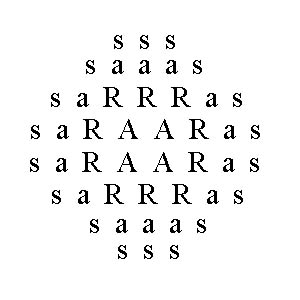

A = Asphaltenes (solute)

R = Resins (dispersant)

a = Small Ring Aromatics (solvent)

s = Saturates (nonsolvent)

Colloidal Dispersion – Solution Hybrid Model of Petroleum

The oil compatibility model is based upon the colloidal dispersion – solution model of petroleum shown above. The asphaltenes, the most aromatic, highest molecular weight fraction, are microscopic solids that are dispersed in the oil by the resins, the next most aromatic, next highest molecular weight fraction. While this asphaltene-resin dispersion is dissolved by the small ring aromatics in the oil, the saturates act as nonsolvents. Thus, the asphaltenes are held in petroleum by a delicate balance that is easily upset by adding saturates or by removing aromatics or resins. One way to upset this balance is by blending crudes with much different amounts of these petroleum fractions. When asphaltenes precipitate, they foul, plug, and coke process equipment, such heat exchangers, furnace tubes, and catalyst beds.

Below are three abstracts for presentations at the International Conference on Petroleum Phase Behavior and Fouling as part of the 1999 Spring AIChE Meeting on March 14-18 in Houston and later published in the following references.

References:

Wiehe, I. A. and Kennedy, R. J., US patent 5,871,634 assigned to Exxon, February 16,1999 and World Patent WO 98/26026.

Wiehe, I. A. and Kennedy, R. J., “The Oil Compatibility Model and Crude Oil Incompatibility”, Energy and Fuels, 14 Jan. 2000, pp 56-59.

Wiehe, I. A. and Kennedy, R. J., “Application of the Oil Compatibility Model to Refinery Streams”, Energy and Fuels, Jan. 2000, pp 60-63.

A Model for Predicting the Compatibility of Crudes and of Processed Oils

It is well known that the asphaltenes in thermally processed, petroleum derived oils have a strong tendency to precipitate when mixed with more saturated oils. However, it is not as well known that the blending of petroleum crude oils can also precipitate asphaltenes (incompatibility) and cause the rapid fouling or coking of refinery process equipment. The Oil Compatibility Model (OCM) has been derived and found to provide a conservative prediction of the compatibility or incompatibility of any number of crude or processed oils.

One basic assumption of the OCM is that a fixed fraction of the resins are associated with the asphaltenes to form the solute and the aromatic-saturate balance of the entire oil determines the solvency of the oil for asphaltenes. This simplification neglects the dynamic dispersant activity of resins towards asphaltenes but enables treating it as a solubility phenomenon. As a result, the predictions are found to be conservative: sometime compatible oils are predicted to be incompatible but incompatible oils are never predicted to be compatible. A second basic assumption is that asphaltenes precipitate at the same solubility parameter of the mixture, no mater whether one is mixing oils or hydrocarbon liquids. This avoids estimating the solubility parameter of the asphaltenes and enables measuring both this flocculation solubility parameter and the solubility parameter of the oil by blending the oil with test liquids, such as mixtures of toluene and n-heptane. Since, by definition, this flocculation solubility parameter is between the solubility parameter of n-heptane and the solubility parameter of toluene, a newly expanded solubility parameter scale is defined that has a value of 0 for n-heptane and a value of 100 for toluene. On this scale, the flocculation solubility parameter is called the insolubility number and the solubility parameter of the oil is called the solubility blending number. The criterion for oil compatibility is that the volume average solubility blending number of the mixture is higher than the insolubility number of any component in the mixture.

Prevention of Fouling by Incompatible Crudes with the Oil Compatibility Model

It is not well known that the mere mixing of crude oils can cause the precipitation of asphaltenes (incompatibility) and result in the rapid fouling of preheat exchangers and the sudden coking of pipestill furnace tubes. With the recent increase in the purchase of opportunity crudes for improving refinery economics, the frequency of incompatible crude fouling/coking incidences has escalated. However, with the Oil Compatibility Model and a few tests on the crude with mixtures of toluene and n-heptane, the insolubility number, measure of asphaltene solubility, and the solubility blending number, measure of oil solvency for asphaltenes, of each crude can be determined. Thereafter, the proportions of any number of oils in a mixture and the correct order of blending can be determined to assure that mixture is compatible. The conservative criterion for oil compatibility is that the volume average solubility blending number of the mixture is higher than the insolubility number of any component in the mixture. One refinery example is when a vacuum pipestill furnace was coked by the blending of incompatible crudes, Souedie and Forties, in the wrong order.

Mitigation of the Plugging of a Hydrotreater with the Oil Compatibility Model

A refinery fixed bed hydrodesulfurization unit processed a wide variety of streams: unprocessed atmospheric and vacuum gas oils, 600 neutral lube extract, propane asphalt, fluid catalytic cracker bottoms, light catalytic cycle oil, heavy catalytic cycle oil, and catalytic kerosene oil. The top of the catalyst bed where the liquid feed entered plugged in two weeks of operation. Once the removed coke was determined to be nearly all organic, the possibility of feed incompatibility (asphaltene precipitation on mixing) was investigated using the Oil Compatibility Model (OCM). Tests with mixtures of oil, toluene, and n-heptane were applied to the two streams found to contain asphaltenes, propane asphalt and fluid catalytic cracker bottoms, to determine an insolubility number, measure of asphaltene insolubility, and a solubility blending number, measure of oil solvency, for each stream. The solubility blending numbers of the remaining streams without asphaltenes were determined by either replacing toluene or n-heptane, depending if it were a solvent oil or a nonsolvent oil, in tests rerun on the fluid catalytic cracker bottoms. As a result, the propane asphalt was determined to be compatible with all other streams but the fluid catalytic cracker bottoms were determined to be incompatible with the unprocessed gas oils and catalytic kerosene oil. The OCM predicted that the design feed mixture was compatible but that incompatible feed mixtures started when higher proportions of unprocessed gas oils began to be processed. This range of incompatibility was verified by direct blending studies. Based upon the predictions of the OCM, the feed mixture to the hydrotreater was kept within the compatible range and no plugging problems appeared in over two years of operation.